Economic Impact of the Retread Tire Industry

Retreaded tires are an economical and environmentally responsible business practice that also contribute jobs and economic value to the u.s. economy.

Author: Josh Abell, PhD

Retreads are tires that are remanufactured by applying a new tread to the tire casing thereby extending its service life, typically by 1-2 times.1 The retreading process is akin to the manufacturing process of new tires for adhering various tire components utilizing a rubber cure process. Tire retreading is a multi-step value chain where the tread rubber is manufactured by a large tire company such as Bridgestone, Michelin and Goodyear and casings are inspected and the tire is remanufactured at one of more than 600 independently owned and operated retread plant locations across North America.2 Many of these retread plants support livelihood by providing jobs in urban and rural communities across the continent

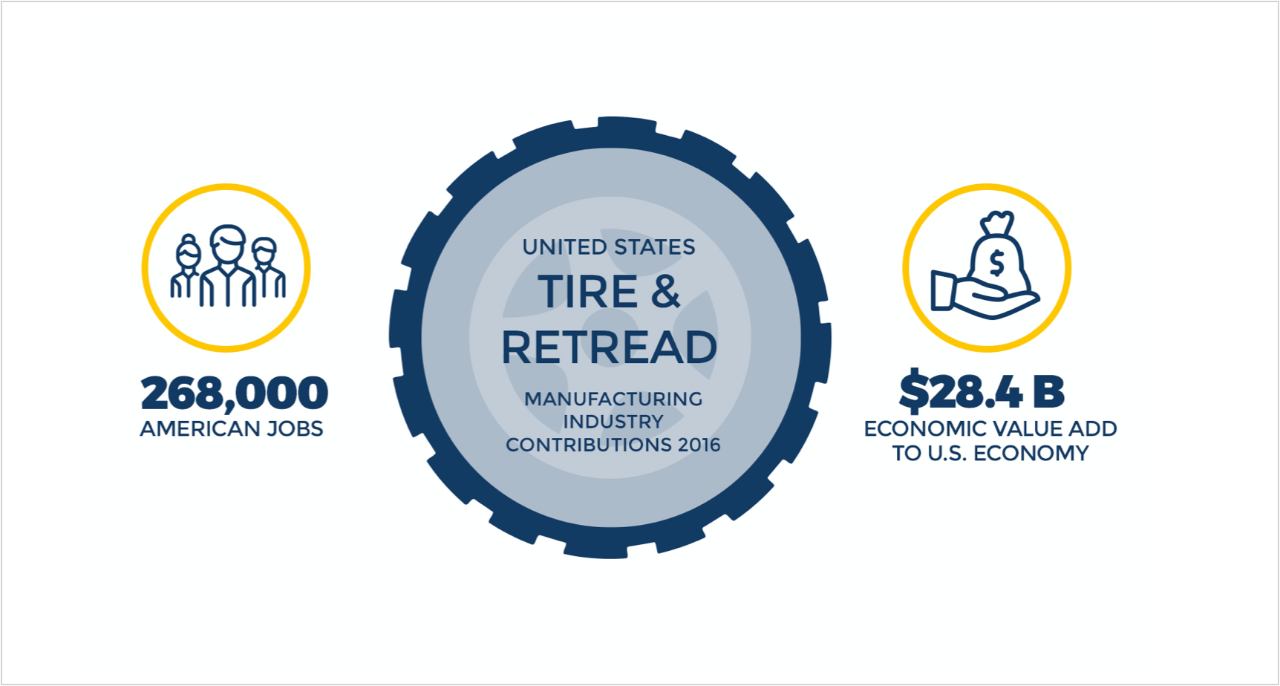

In 2016, the commercial tire replacement market in the United States is estimated to be approximately 33 million units annually, of which nearly half (14.5 million or 44%) were retreads.2 In a 2008 report by the Department of Manufacturing Engineering at Boston University, the retread industry represented the largest remanufacturing sector in the United States contributing significantly to the overall economy.3 Economic modelling suggests the combined economic activities of the retread industry contributed $28.4B in value to the U.S. economy and supported 268,000 direct, indirect and induced jobs in 2016.4 The industry is driven by local small to medium businesses catering to the products and services needs of the trucking industry, providing them great value for their money and keeping them on the road.

Retreads are an economical and environmentally responsible business practice. Retreaded tires offer significant cost savings (up to $3B annually) across fleets by maximizing casing asset utilization and extending the life of a tire.5 Additionally, retreads cost up to 50 percent less than comparable new tires and many perform as well as premium new tire offerings.6

The benefits of retreading go beyond cost savings. Retreaded tires require fewer raw materials and less energy to manufacture compared to new tires, thus, benefiting the environment.5 Retreading tires also results in diversion of solid waste from landfills, which has been shown in California7 to not only positively impact the environment but also the economy. The challenge facing the retread industry going forward will be to grow usage of retreads by demonstrating the value that retreads deliver to the overall economy and the environmental impacts to our society.

- Bridgestone BASys Manufacturing data analysis of over 700,000 tires from a 12-month period beginning June 2016 on the average number of times a tire was retreaded using a premium casing.

- Ulrich, Bob. “2017 Facts: Overview” Modern Tire Dealer. Jan 2017: 26-44. Print.

- Hauser, W., and Lund, R., Remanufacturing: Operating Practices and Strategies, Department of Manufacturing Engineering, May 2008. Print.

- Bandag commissioned Duke University’s Center for Sustainability and Commerce to perform IMPLAN economic modeling to determine the impact retreading commercial tires has on the North American economy. A more comprehensive report will be release in due course.

- "About Retreading" Tire Retread & Repair Information Bureau, TRIB, 2013, http://www.retread.org/about-retreading.

- http://americamovesbytruck.com/rollingresistance.php last accessed: 11/28/17

- INTEGRATED WASTE MANAGEMENT BOARD “Diversion Is Good for the Economy: Highlights from Two Independent Studies on the Economic Impacts of Diversion in California” Mar 2003. Print.The economic impact of waste diversion per ton is twice that of disposal where the market is developed and supported for recycling.